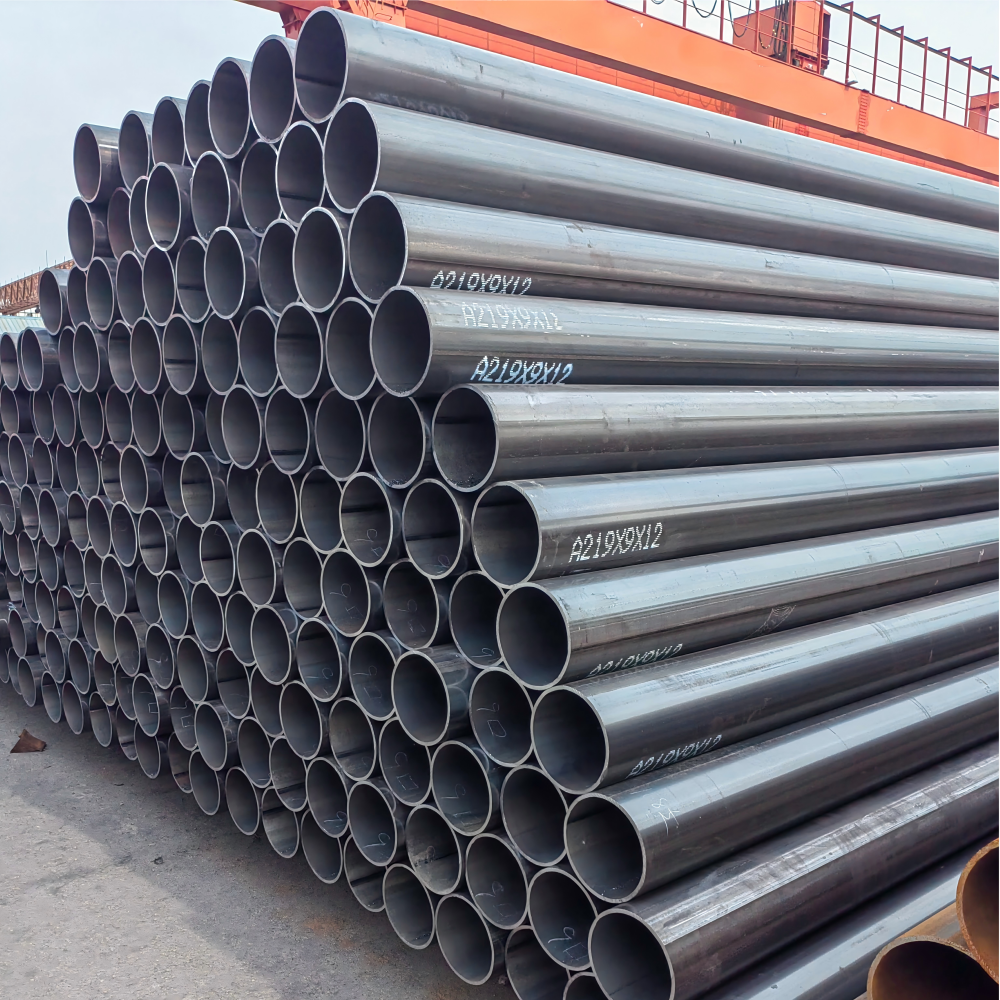

Welded steel pipe refers to a steel pipe with a seam on the surface, made by bending steel strip or plate into a round, square, or other shape and then welding it. The raw material used for welded steel pipe is steel plate or strip.

Since the 1930s, with the rapid development of continuous rolling production of high-quality strip steel and advancements in welding and inspection technology, weld quality has continuously improved, and the variety and specifications of welded steel pipes have expanded. Welded steel pipes have replaced seamless steel pipes in a growing number of applications. Welded steel pipes offer lower costs and higher production efficiency than seamless steel pipes.

Welding Method Classification

Based on the welding method, welded steel pipes can be categorized as arc welded pipes, high-frequency or low-frequency resistance welded pipes, gas welded pipes, furnace welded pipes, and Bondi pipes.

Electric welded steel pipes are used in oil drilling and machinery manufacturing, among other applications.

Furnace welded pipes can be used as water and gas pipes, large-diameter straight seam welded pipes are used for high-pressure oil and gas transportation, and spiral welded pipes are used for oil and gas transportation, piles, and bridge piers. Classification by weld seam shape: Pipes can be divided into straight seam welded pipes and spiral welded pipes. Straight seam welded pipes feature a simple production process, high efficiency, low cost, and rapid development.

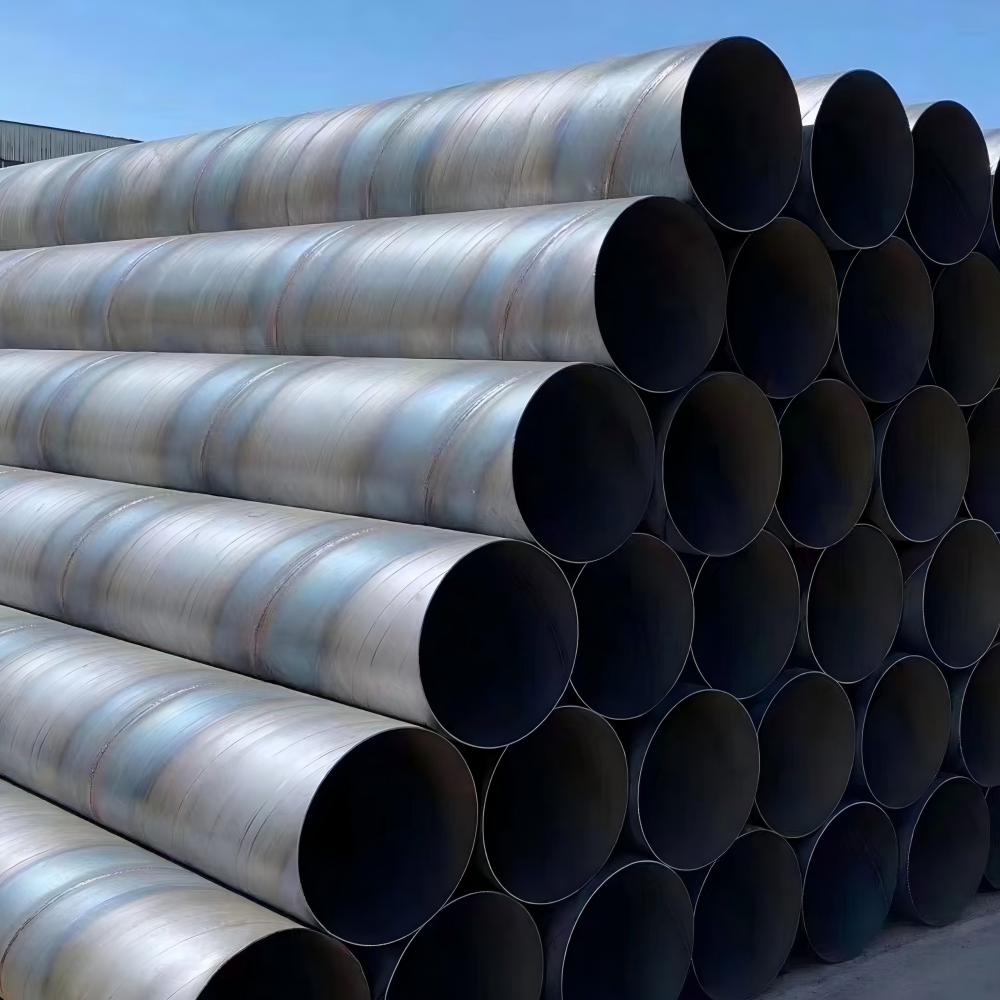

Spiral welded pipes are generally stronger than straight seam welded pipes. They can be produced from narrower billets, and pipes of varying diameters can be produced from billets of the same width. However, compared to straight seam pipes of the same length, the weld seam length increases by 30-100%, and production speeds are lower. Therefore, smaller diameter pipes are mostly welded using straight seam welding, while larger diameter pipes are mostly welded using spiral welding.

Spiral welded steel pipes are categorized into automatic submerged arc welded pipes and high-frequency welded pipes.

a. Spiral automatic submerged arc welded steel pipes are classified as Class A and Class B based on the pressure of the conveying medium. Category A pipes are generally welded from ordinary carbon steels Q235, Q235F, and ordinary low-alloy structural steel 16Mn. Category B pipes are welded from steels such as Q235, Q235F, and Q195 and are used for conveying low-pressure fluids.

b. Spiral Seam High-Frequency Welded Steel Pipes: Spiral seam high-frequency welded steel pipes have no unified product standard and are generally made from ordinary carbon steels such as Q235 and Q235F.

Classification by Application

Based on their application, they are categorized into general welded pipes, galvanized welded pipes, oxygen-blow welded pipes, wire conduits, metric welded pipes, roller pipes, deep-well pump pipes, automotive pipes, transformer pipes, electric-welded thin-walled pipes, electric-welded special-shaped pipes, and spiral welded pipes.

General Welded Pipes

General welded pipes are used to convey low-pressure fluids. They are made from Q195A, Q215A, and Q235A steels. Other mild steels that are easily welded can also be used. Steel pipes undergo water pressure, bending, and flattening tests, and have specific surface quality requirements. Delivery lengths are typically 4-10 meters, and custom lengths (or multiples) are often required. Welded pipe specifications are expressed in nominal diameter (in millimeters or inches). The nominal diameter differs from the actual diameter. Welded pipes are available in two types: standard and thickened, depending on the specified wall thickness. Steel pipes are also available in threaded and unthreaded versions, depending on the end type.

Galvanized Steel Pipes

To improve corrosion resistance, standard steel pipes (black pipes) are galvanized. Galvanized steel pipes are available in hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing provides a thicker coating, while electro-galvanizing offers lower costs.

Special Shaped Pipes

Welded from ordinary carbon structural steel and 16Mn steel strip, these pipes are square, rectangular, cap-shaped, and hollow-coated steel pipes for doors and windows. They are primarily used for agricultural machinery components, steel windows and doors, etc.

Electro-welded Thin-Walled Pipes

Mainly used in furniture, toys, and lighting. Thin-walled pipes made from stainless steel strip are currently widely used in high-end furniture, decoration, and railings.

Spiral welded pipe is made by rolling low-carbon structural steel or low-alloy structural steel strip at a specific spiral angle (called the forming angle) into a tube billet, which is then welded together. This allows the production of large-diameter steel pipes from narrower strips. Spiral welded pipe is primarily used in oil and natural gas pipelines, and its specifications are expressed as outer diameter x wall thickness. Spiral welded pipe is available in single-sided and double-sided welds. The pipe must meet regulatory requirements for hydrostatic testing, weld tensile strength, and cold bending properties.

Contact Us

- +86-13920256138

- +86-13920256138

- +86-13920256138

- krisfyt65@gmail.com

- +86-13920256138